Equipment from China for agricultural product processing

We offer the latest models of popular equipment and processing lines for agricultural products. Our competitive prices and transparent terms are complemented by fast delivery.

Contact us and get a free consultation.

We work with the best manufacturers

The mung bean processing and sorting line is a specialized equipment for processing legumes that automates the process of cleaning, sorting and preparing mung beans for packaging. First, the beans enter the line, where they undergo primary cleaning from dust, stones and other impurities using vibrating sieves and magnetic separators. Next, using optical sorters, the beans are sorted by size and quality, selecting defective or damaged ones. In some cases, blanching is carried out, which helps preserve the color and texture of the beans and destroy microorganisms. After processing, the beans are dried to an optimal moisture level, which prevents them from rotting and extends their shelf life. Finished beans are packed in sealed packages such as bags or containers. The line ensures high quality, efficiently processing large volumes of products, preserving nutrients and vitamins in the beans. The advantages of the system include high product quality, efficiency due to automation and preservation of nutrients. The line is ideal for processing beans, creating semi-finished products (dried or frozen) and bean mixtures for soups and other dishes.

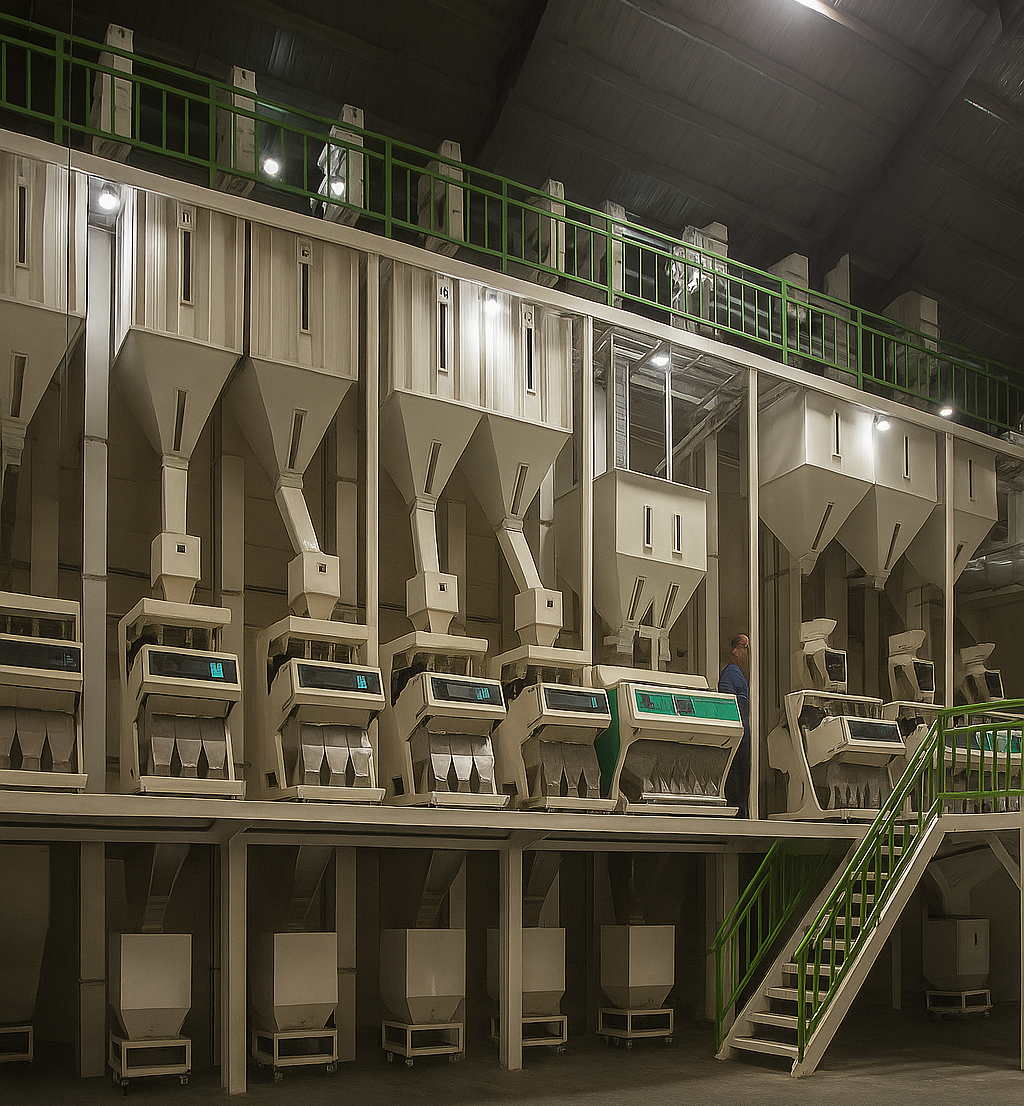

Grain mills are specialized machines for processing grain crops into flour and other products. They can range from small home mills to large industrial plants that process large volumes of grain. Mills can produce different types of flour (wheat, rye, corn), groats (buckwheat, oat), bran, as well as finely ground products for specialized diets or recipes. The process begins with loading the grain, which is pre-cleaned of impurities, stones and contaminants. The grain then passes through millstones or hammer mechanisms, depending on the type of mill. Millstones provide a more uniform grind, while hammer mills use hammers to break up the grain. The grinding can be multi-layered, first coarse, then finer, which allows you to get flour of the desired degree of grinding. After milling, the product is sorted to separate the flour by type and quality, which ensures the homogeneity of the product. Finished products, including flour and grains, are packed into bags or containers using automated packaging machines. The benefits of using grain mills include high quality flour, product variety for different markets, and the efficiency provided by automation, which allows for increased production volumes and reduced costs.

Grain and rice processing equipment includes various machines and lines designed to clean, process, mill and pack grain crops. These plants transform raw materials into finished products such as flour, cereals and rice. Production processes include the manufacture of various types of flour (wheat, rye, corn), cereals (buckwheat, rice, oat) and processed rice, as well as by-products such as bran and seeds that can be used in animal feed or other products.

The processing process begins with cleaning the grain and rice from impurities such as stones and dust using vibrating sieve machines and magnetic separators. The raw materials are then dried to prevent spoilage, after which they are ground in millstone or hammer mills to obtain flour or cereal of the desired consistency. The finished products are sorted by size and quality to ensure uniformity. The products are then packed using automated packaging machines into bags, boxes or containers.

The advantages of grain and rice processing include increased shelf life of processed products, ease of storage and transportation, and product diversity to meet the needs of different consumers.

Fruit and vegetable drying equipment is designed to remove moisture from foods, which helps extend their shelf life, preserve nutrients, and prevent spoilage. This process also makes it easier to transport and store foods. The equipment can produce dried fruits such as apples, pears, mangoes, and vegetables such as carrots, tomatoes, and mushrooms. Dried foods are used in snacks, baked goods, soups, and instant mixes.

The process begins with preparing the food: it is washed, peeled, and cut into uniform pieces. It is then placed in drying chambers, where various drying methods are used, such as hot air, vacuum drying, or convection. After drying, the food is cooled and sealed in airtight packages to prevent moisture from entering.

The benefits of drying include preserving vitamins and minerals, extending the shelf life of food without the use of refrigerators, and making it easy to transport and use in cooking.

Equipment for packaging agricultural products includes machines and lines for automating the process of packaging fresh, processed and processed products. This equipment protects products from damage, contamination and helps to increase their shelf life. It can be used to pack fresh vegetables, fruits, herbs, as well as canned, frozen or freeze-dried products.

The packaging process includes several stages: pre-processing of products, washing and sorting to remove dirt and damaged elements, then packaging using various methods such as vacuum packaging, heat shrink or flexographic printing. After filling, the package is closed and sealed to protect against external factors. Information about the composition and expiration dates of the products is applied to the package.

The advantages of packaging include protecting products from mechanical damage and contamination, increasing shelf life, ease of storage and transportation, and informativeness of the packaging for consumers.

Blast freezing equipment is designed to quickly freeze fresh agricultural products such as fruits, vegetables, meat and fish. This process helps to preserve the nutrients, texture and taste of the products, preventing damage to the cellular structures due to the formation of large ice crystals.

The process begins with the preparation of the products: they are washed, peeled and cut as needed. The prepared products are then placed in blast freezing chambers, where the temperature is quickly lowered to -30 °C or -50 °C. This allows the products to be frozen without damaging their structure. After freezing, the products are transferred to cold storage chambers for storage at a stable temperature.

The benefits of blast freezing include the preservation of nutrients, texture and taste, an increase in shelf life, and flexibility in production, which allows for the rapid processing of large volumes of products, especially during the harvest season.

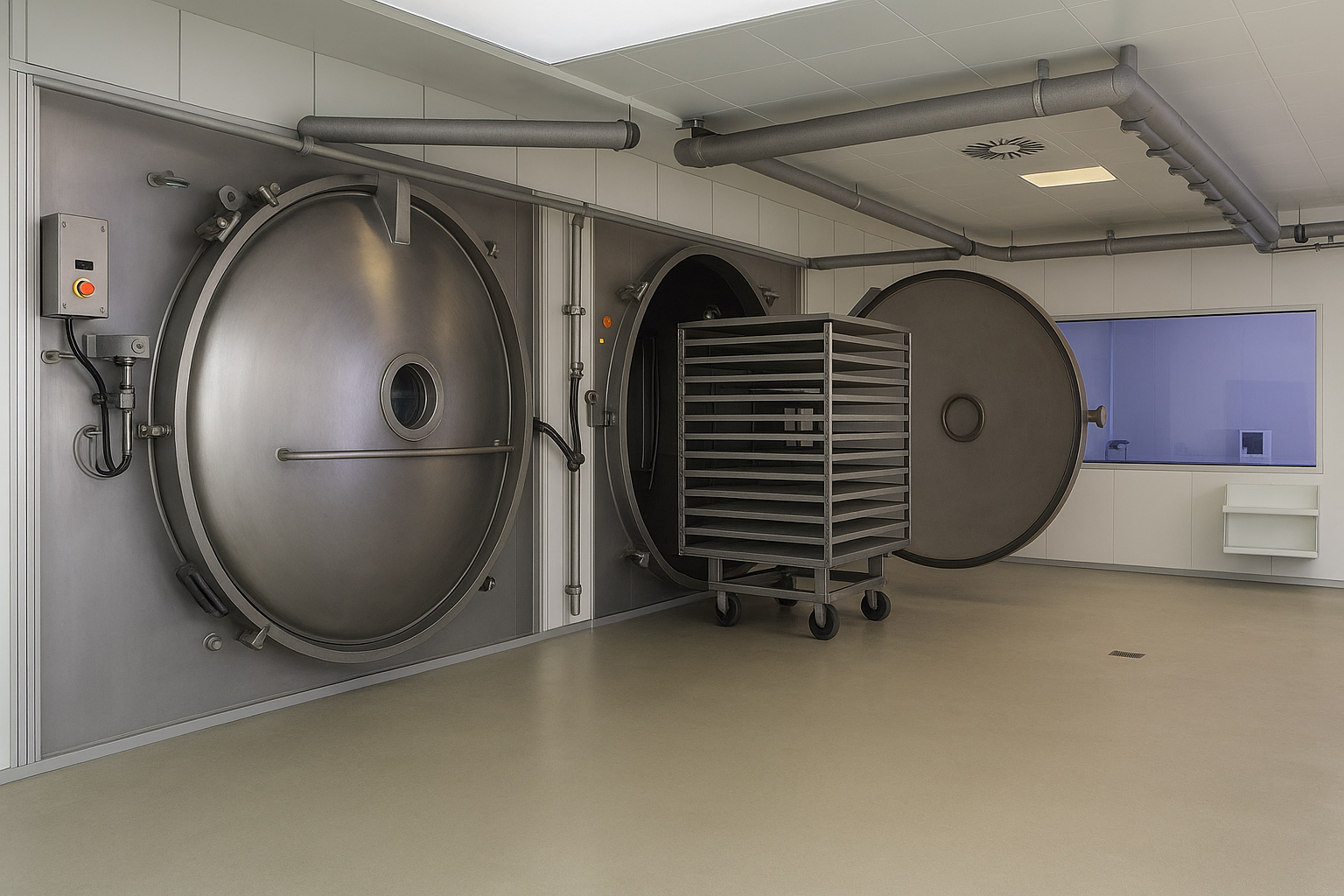

Freeze-drying equipment is designed to remove moisture from fruits and vegetables using a sublimation process in which ice turns into steam, skipping the liquid phase. This method helps preserve the nutrients, flavor, aroma and texture of the food, and allows for long-term storage without preservatives.

The process begins with preparing the food: it is washed, peeled and cut. In some cases, fruits and vegetables are blanched to preserve color and texture. The food is then frozen in special chambers, after which it is placed in a vacuum chamber. Here, low pressure is created and the temperature gradually increases, which allows the ice to turn into steam. This process removes 90-95% of the moisture, leaving the food light and durable. Finished freeze-dried food is packed in airtight containers to protect it from moisture.

The benefits of freeze-drying include preserving nutrients, easy storage and transportation, a long shelf life without refrigeration and ease of preparation – just add water to reconstitute the food

Refrigeration units are devices designed to create and maintain low temperatures in refrigeration systems. These units are used in various industries, including food, medicine, trade and climate control. The main function of the units is to produce cold for cooling or freezing products and maintaining a set temperature in refrigeration units.

The process begins with compression, where the refrigerant is compressed, increasing its temperature and pressure. It then passes through the condenser, where it gives off heat to the environment and turns into a liquid. The liquid refrigerant passes through an expansion valve, where its pressure decreases and it evaporates, cooling the environment. Ultimately, this process is repeated, ensuring stable operation of refrigeration systems.

The benefits of refrigeration units include energy efficiency, reliability and versatility. They play a key role in maintaining high-quality storage of products and other goods that require special temperature conditions in various sectors.

Glass greenhouses are glass-covered structures designed to grow plants in controlled conditions. They provide maximum sunlight, which promotes efficient photosynthesis and rapid plant growth. Glass lets in more light, which is especially important for heat-loving crops such as tomatoes, cucumbers, peppers, and flowers. Greenhouses protect plants from adverse weather conditions, creating a comfortable environment for their growth.

A ventilation system is used inside glass greenhouses to regulate temperature and humidity. Automatic windows and fans maintain optimal conditions, allowing plants to be successfully grown at any time of year. Heating and cooling systems help adapt the climate to seasonal changes.

One of the key advantages of glass greenhouses is their durability. Glass is a durable material that is resistant to external influences, making the greenhouse durable and reliable. Glass greenhouses are also aesthetically pleasing, making them an excellent solution for landscape design.

The benefits of glass greenhouses include durability, maximum use of sunlight, efficient climate control, and energy efficiency. These greenhouses provide ideal conditions for growing plants, making them a must-have for farmers and gardeners.

Film greenhouses are structures covered with film, designed for growing plants in controlled conditions. These greenhouses provide protection for plants from adverse weather conditions, pests and diseases, creating an optimal environment for their growth. In such greenhouses, it is possible to maintain the necessary climatic conditions for various agricultural crops, including vegetables, fruits and greens.

Film greenhouses allow you to create an ideal microclimate, retaining heat and maintaining the necessary humidity, which contributes to the rapid growth of plants. Inside the greenhouses, ventilation systems are used that regulate the temperature, as well as irrigation and fertilization systems that provide plants with all the necessary nutrients. Film coverings protect plants from insects and diseases, acting as a barrier between the external environment and the plants.

One of the main advantages of film greenhouses is their efficiency and cost-effectiveness. They help to significantly reduce the cost of fertilizers and pesticides, and also save resources by creating optimal conditions for plant growth. Film greenhouses are also highly flexible, easy to install and can be moved depending on needs. They are an affordable and convenient solution for farmers and gardeners, providing high yields at minimal cost.

Cold rooms are specially equipped rooms for storing goods at controlled low temperatures. They can have different sizes and designs, from small rooms for restaurants to large warehouse chambers for distribution centers. Cold rooms are widely used in industries such as food, pharmaceuticals and logistics, where precise control of temperature conditions is required.

The main characteristics of cold rooms include temperature conditions, which can vary from 0 ° C to -18 ° C, depending on the type of stored products. For example, for meat and dairy products, the optimal temperature is from 0 ° C to + 4 ° C, and for frozen products – below -18 ° C. The chambers are equipped with effective insulation, which helps to minimize heat loss, as well as temperature and humidity control systems, which allow for accurate monitoring of storage conditions.

The benefits of cold rooms include providing stable and optimal conditions for storing products, which helps preserve their quality and nutritional properties. Long-term storage at a constant temperature helps to avoid spoilage and extend the shelf life of products. Such chambers are convenient for transporting goods over long distances, especially for perishable products such as seafood, meat and medicines.

Our services

SUPPLIER SEARCH AND VERIFICATION IN CHINA

Equipment search through partner databases, by countries worldwide, and among industry leaders.

BEST PRICES FOR EQUIPMENT FROM CHINA

Our local representatives will get you the best prices directly from manufacturers.

COUNTERPARTY VERIFICATION IN CHINA

Verification of the company’s registration date, licenses, litigation history, and actual address.

DELIVERY TERMS FROM CHINA

We will deliver your order on the most favorable logistics terms for you (air, rail, or truck).

CONTRACTING

Preparation of export-import contracts: Customs clearance procedures in China and customs clearance in Uzbekistan.

QUALITY CONTROL

Our local representatives control the entire production process of equipment and goods.

LOGISTICS

Supervision of the loading process, providing photo and video reports.

INSTALLATION

Commissioning works and staff training in Uzbekistan.

Our additional services

The main goal of the company Grande is to organize mutually beneficial cooperation between entrepreneurs and companies from around the world and China.

Fast and reliable delivery of goods from China to any destination.

Find a partner for cooperation with China right now.

Reliable purchase of equipment from China with guaranteed quality and reliability.

High-quality verification of Chinese companies before cooperation and investment.

Reliable delivery of goods from China directly to your warehouse.

Wholesale purchase of goods from China on favorable terms.

Directions

The company “Grande” offers an unlimited selection of high-quality, high-tech equipment, machines, installations, and technical tools from leading Chinese manufacturers on a turnkey basis and provides recommendations to its clients on all matters related to purchasing equipment and goods.

We will assist you in selecting agricultural equipment and machinery for growing, harvesting, sorting, and processing fruit and vegetable crops, as well as other types of agricultural production.

Supply of high-quality equipment and belts for food production. Familiarize yourself with the list of main types of machines used in the food industry.

Comprehensive solutions for the light industry from China at affordable prices. Equipment for raw cotton processing, textile printers, weaving machines, textile dyeing equipment, and more.

We offer a wide range of equipment for the production of construction materials. With us, you’ll find machinery for manufacturing paints and varnishes, equipment for producing ceramic materials and products, as well as other types of equipment at the best prices.

Specialized machinery for use in the mining industry, including rock crushing equipment, mineral exploration tools, equipment for extracting mining and chemical raw materials, and other machinery from Chinese manufacturers at the best prices.

We offer innovative equipment for extracting metals from ores or other types of raw materials, as well as technology related to altering the chemical composition, structure, and properties of metal alloys, and the production of various metal products from them.

Turnkey logistics.

Delivery of goods, raw materials, and materials directly from China to your city.

Trust your business to professionals

Our company has extensive experience in direct cooperation with Chinese companies. Grande specialists help businesses daily to purchase high-quality products from trusted Chinese suppliers. Moreover, Grande will assist you with all documentation and ensure the delivery of your goods to your warehouse or facility.